Outdoor porcelain pavers have become one of the can’t-miss products in the landscaping industry for their sleek appearance, all-weather durability and low-maintenance appeal.

Perhaps their most attractive attribute: looking and feeling clean-cut.

With sharp edges and smooth textures, porcelain pavers are built to impress with trendy, contemporary designs. But as good as they look, they are delicate and can be damaged if not cared for properly. In fact, how you handle porcelain pavers is crucial to their wellbeing.

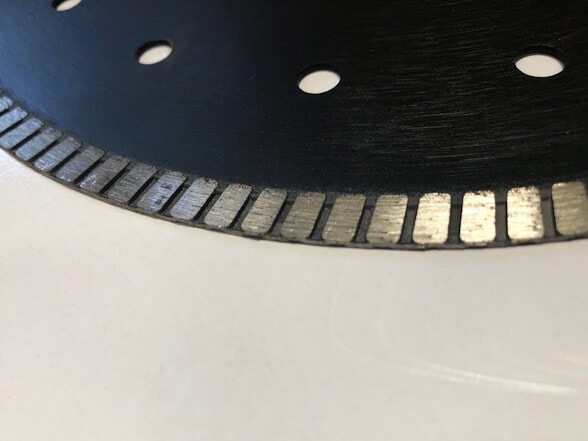

For landscape contractors, it all starts with making the first cut.

Cutting porcelain pavers correctly requires practicing patience and using the best tools to complete the task. Like any job, the difference between a good result and a bad one comes down to knowledge and execution, but what is most important is attention to the finer details.

For that, Hedberg Supply suggests using a wet table saw like the MK Diamond 100-24 or 101, an industry-recommended device that eliminates broken pieces during the shaping and sizing process.

While it is important to complete your projects in a fast, timely manner to keep homeowners happy and move on to your next job, rushing the cutting process is one of the worst things you can do on the jobsite. Again, failure to deliver anything less than what is known to be a spotless product would be cause for concern. Designed to make your job easier and more efficient, wet table saws guarantee straight, clean and defined pavers — and happy customers that will come back to you for more.

PRODUCT DETAILS

Voltage: 120V

Horsepower: 1.5 hp

Blade RPM: 3,450

Blade Size: 10”

Arbor Size: 5/8”

Depth of Cut: 3”

Length of Cut: 20”

Diagonal Cut: 14”